Radiation Protection System

![]()

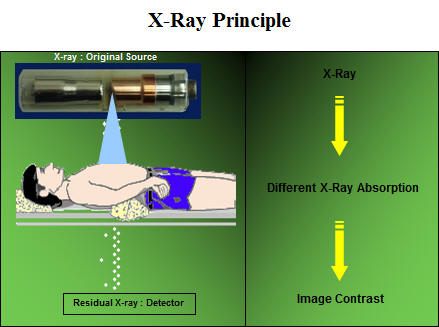

X-RAY Shielding Systems

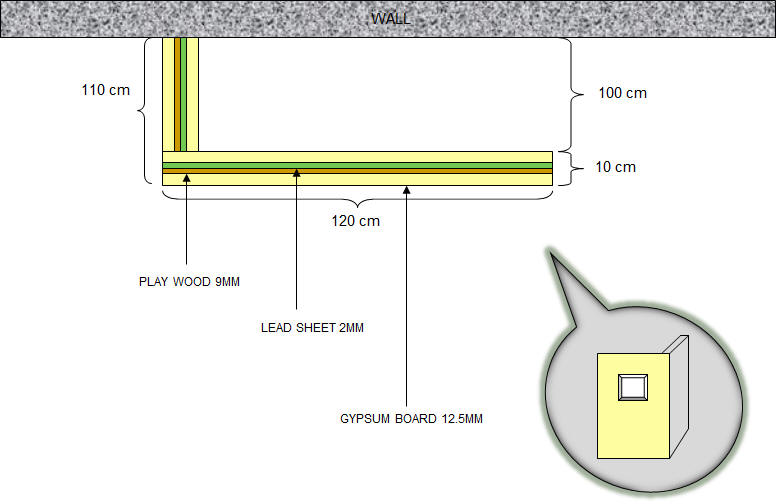

X-Ray shielding systems consist of lead-lined plywood or lead-lined drywall paneled walls, lead-lined doors, and leaded viewing windows, all of which are based on the final physics design and architectural requirements. Shielding can be used in both new facilities and to upgrade existing rooms to accommodate an x-ray system.

DKS works to provide competitively-priced solutions for full systems or components. Our involvement in X-Ray shielding systems can range from supplying the products to supervising construction and installation to providing complete turnkey services. Our qualified teams of designers have a proven track record of X-Ray installations throughout the world, and always work one-on-one with clients to create the most cost-effective solutions.

USES

DKS X-Ray Shielding Systems are used for rooms with low energy x-rays and gamma rays for both medical and industrial uses.

SHEET LEAD

DKS Offers Sheet Lead for Many Applications Including:

Radiation Shielding - Laboratories, Hospitals, Dental Offices and Veterinary Clinics,•Construction - Roofing, Flashing and Waterproofing•Corrosion Protection - Acid Storage and Handling - Autoclaves - Precipitators•Movable Lead Screens•Sound Barriers and Sound Proofing•Nuclear Energy Shielding•Tank Lining•Vibration AbsorbersDKS provides Sheet Lead with a consistent and high density manufactured from pure lead conforming to ASTM B-29, B-749 and Federal QQ-L-201F, QQ-L-171E. We use only the purest lead available. Our sheet lead is 99.94% pure lead. Absolutely no refining is performed in the manufacturing of our sheet lead. DKS is only interested in providing its customers with the highest quality sheet lead available in the market place today.

drywall is laminated with sheet lead that is designed to cover necessary surfaces or walls in a room requiring radiation shielding. It is affixed to surfaces or walls ensuring a continuous layer of sheet lead under the drywall to a specified height. It is used in new construction or shielding upgrades/renovations for P.E.T and other types of diagnostic imaging rooms.

RECOMMENDED LEAD SHEET THICKNESS FOR X-RAY ROOMS

Recommended Lead Sheet Thickness' for X-Ray Rooms

X-Rays Generated by Peak

Minimum Thickness of Lead

Weight per Square

Voltages Not Exceeding

Millimeter

Inches

Foot in Pounds

75 kv

1

0.039

2 1/2

100 kv

1.5

0.059

4

125 kv

2

0.079

5

150kv

2.5

0.093

7

175 kv

3

0.118

8

200 kv

4

0.157

10

225 kv

5

0.197

13

300 kv

9

0.354

24

400 kv

15

0.591

38

600 kv

34

1.343

81

900 kv

51

2

120

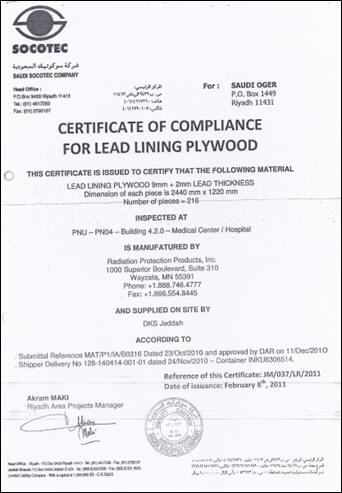

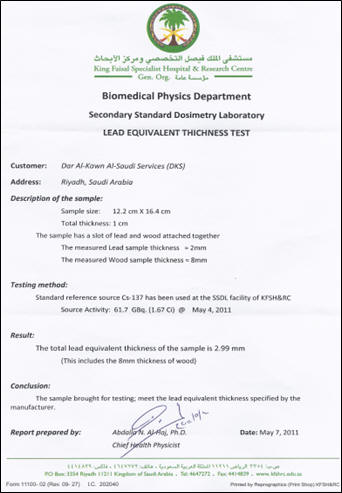

LEAD APPROVAL AND TESTING CERTIFICATES FROM CERTIFIED ORGANIZATIONS

LEAD-LINED DRYWALL

DKS lead-lined drywall (also known as lead-lined sheetrock or gypsum wallboard) is designed to provide radiation shielding in the walls and ceilings of x-ray and gamma ray rooms in a range of medical and industrial facilities, including chiropractic, dental, and veterinary offices. This product also has significant soundproofing capabilities, making it useful in various acoustical and industrial applications.

LEAD-LINED PLYWOOD

lead-lined plywood products provide radiation shielding for walls, ceilings, and floors in new construction or room upgrades for medical diagnostic and industrial modalities. All standard lead-lined plywood panels are formaldehyde-free, fire-rated plywood permanently laminated with uniform, defect-free lead of a specified thickness. To prevent leakage between panels, DKS supplies and can install lead strips of equal thickness.

We offer several different lead thicknesses to accommodate various physics requirements and have the ability to customize plywood products to suit specific needs.

USES

•Shielding• PET/CT rooms

• HDR rooms

• Other diagnostic and industrial modalities

LEAD GLASS

Lead Glass available cut to size as large as 48" x 96” Smaller sizes cut to order Lead equivalencies from 2mm to 3mm Max. Lead Equivalency

1.8 mm -2.0mm 2.5-2.7 mm 3.0-3.2 mm

Benefits:

Shields against X-Rays from equipment in the 100 to 300 kV range High barium and lead content for optimum protection Neutral appearance Product of extensive research and development Marshield quality

Applications:

Viewing windows and insulating glazing for X-Ray rooms

Screens for medical diagnostics

Protection windows in laboratories

Lenses for safety goggles

Airport security X-Ray glass

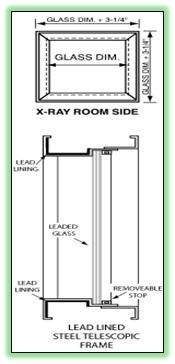

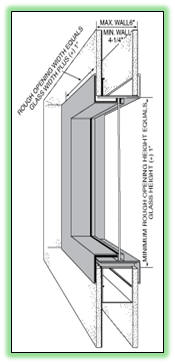

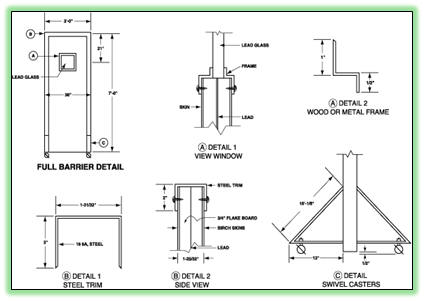

LEAD LINED WINDOW FRAMES

Lead lined view window frames

Standard Steel Telescopic Lead Lined Frames match our Hollow Metal Door Frames. These lead lined window frames can be manufactured to accept any thickness of leaded x-ray glass or leaded acrylic. Standard Lead Lined Steel Telescopic Frames can be steel braced for maximum strength.

The adjustable lead lined steel telescopic frames adjust to wall thicknesses of 4-1/4" to 6". Our lead lined steel telescopic frames can be supplied with optional voice transmission.

Lead/splayed control frames

Leaded window frames manufactured of solid lead 3/16" thick. Will accept up to 2" of leaded x-ray glass and can have voice passage slot. May be used with overlap face on walls up to 5-3/8" thick over all with frame 5-3/4". All leaded window frames come with 1/2" removable stops.

Special construction of leaded frames available to meet your specifications (i.e. special steel reinforcement, wider wall thickness, special sizing, etc.).

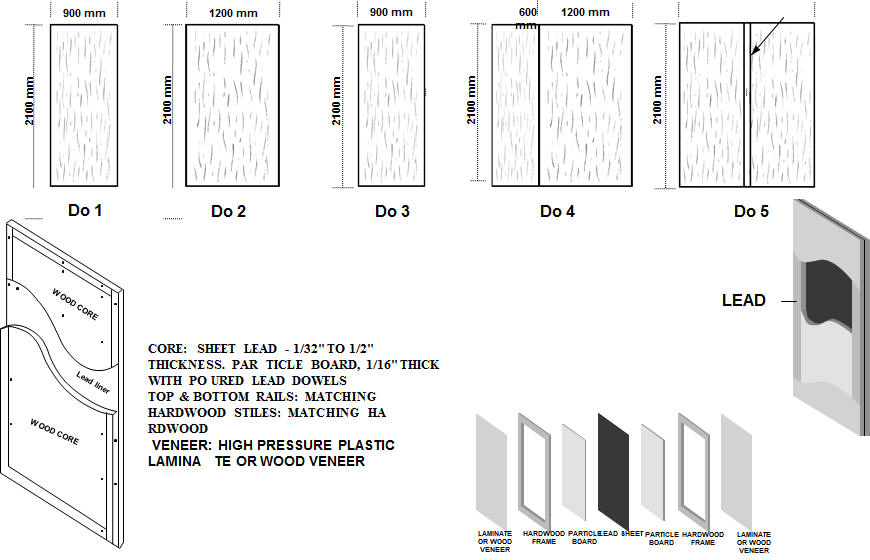

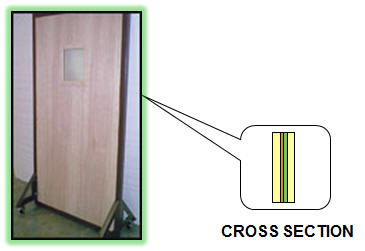

LEAD-LINED DOOR SYSTEMS

Lead Lined Doors are an attractive way of shielding X-Ray, PET/CT, or nuclear medicine rooms. Several options are offered (wood type, grade, window options, and cuts) to ensure your shielded door will blend with any room’s décor. Three types are available:

•Lead-lined, fire-resistant, 20-minute label wood•Lead-lined, non-rated, solid core wood•Lead-lined hollow metalDoors come in a variety of shielding thicknesses, with lead from 1/16” to ¼”, so they can be used for a variety of modalities,

Uses:

•Shielding rooms with x-rays, gamma rays, and PET/CT•Shielding HDR enclosures•Industrial and acoustical

LEAD LINED DOOR

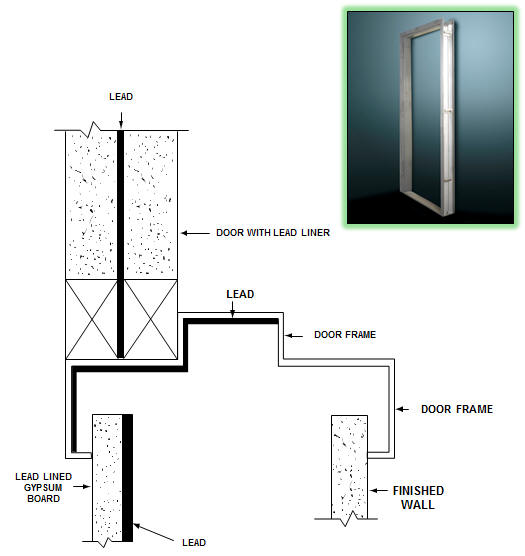

STANDARD LEAD LINED DOOR FRAMES

Door Frames

lead-lined, hollow-metal door frames support the heavy weight of lead-lined doors while maintaining an aesthetically pleasing appearance. These doors and frames can be designed to suit various wall sizes and hardware specifications. Two types are available:

•Hollow-metal knockdown frames•Three-piece style and intended for use in existing construction

• Hollow-metal welded frames•One-piece style•Welded, mitered, and reinforced corners for a strong, continuous seal•Intended for use in new construction projects•Installed during the wall framing process

Out-swing and in-swing door configurations and custom sizes are offered. All NELCO door frames are manufactured from cold-rolled steel and prime-painted. A uniform sheet of lead in a specified thickness is permanently fixed around the perimeter of each frame.

Uses

•Shielding rooms with x-ray, gamma ray, or PET/CT modalities•Shielding HDR enclosures (door frames only)

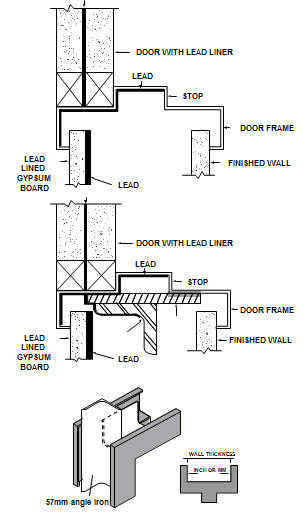

LEAD LINED DOOR FRAMES

STANDARD LEAD LINED DOOR FRAMES

Radiation Protection Products' Standard Lead Lined Door Frames consist of 16-gauge steel, a 2" face, and a 5-7/8" jamb depth. They are set up and welded and can accommodate up to 1/2" thick lead lining. Our Lead Lined Door Frames are shipped with steel stud anchors that can be attached to the door frame either by welding or with steel fasteners if the lead lining does not exceed 3/32" thick

We require the use of an Angle Iron for added support on Lead Lined Door Frames that require 1/8" thick lead or higher. These Angle Irons can be spot welded to the steel stud or pre-drilled and bolted to the steel stud.

*We do offer angle irons on our lead lined door frames that are below 1/8" thick lead if requested.

CUSTOM LEAD LINED DOOR FRAMES

We can supply knock down, slip and other lead lined frames upon request. Our Lead Lined Frames can also be equipped with the type

of anchors necessary for any given situation (wood stud anchors, masonry strap anchors, etc.). Although our standard Lead Lined Door Frames consist of 16-gauge steel, we offer frames at 14-gauge and 12-gauge as well

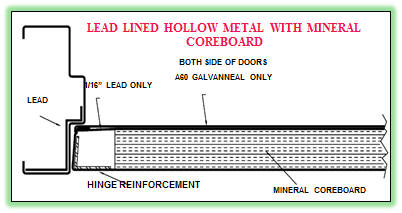

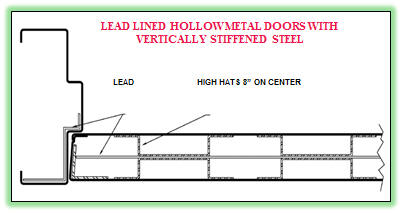

LEAD LINED HOLLOW METAL DOORS

• Coreboard is adhered to the steel

• Lead lining is adhered to the coreboard

• Mineral coreboard door is manufactured with A60 Galvanneal

• High hats 8” on center welded to pan and cover

• Steel stiffened doors are manufactured with cold rolled steel

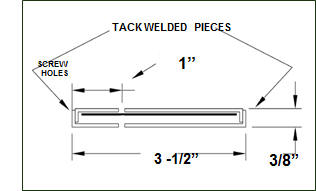

• Astragal is the same material as doors

• Lead thickness will be same as door

• ends will be capped

• Shipped with holes for mounting screws

All our Hollow Metal Lead Lined Doors are manufactured with A60 galvanneal steel or cold rolled steel in 14 gauge

or 16 gauge.

Our Hollow Metal Lead Lined Doors can be filled with mineral core board or they can be vertically steel

stiffened. The edges of our doors are continuously seam welded, ground and filled to ensure a smooth finish.

The top and bottom of the doors are reinforced with continuous steel channels, spot welded to both sides of the door. All doors come with 11 gauge steel angles, 12” long for hinge rein-forcement. All doors can be fit with a door lite kit and leaded glass. UL labels available upon request.

Doors meet or exceed the following:

• ASTM A526 (Galvanneal)

• ASTM A366 (Cold Rolled Steel)

• HMMA 861-00 For Commercial

Hollow Metal Doors and Frames

• SDI-100, Grade II, Heavy Duty Model 3, Seamless Hollow Metal Construction

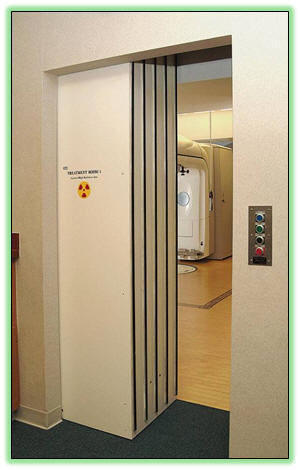

RADIATION THERAPY SLIDE DOOR

DKS supplier in USA has the largest installed base of shielded therapy doors in the Americas.

Slide Door Systems are designed, manufactured, and installed to meet the demanding needs of radiation therapy departments. These systems allow for the elimination of vault mazes and can also increase patient throughput. With a variety of thicknesses available, slide doors are acceptable for use in rooms with high and low energy machines.

Standard slide door packages include the steel-faced door, required shielding materials, a support and rail system, operating system, safety features, and installation.

Our supplier also offers Swing Door systems and an array of services, from helping you chose the best equipment for your facility to aiding in the design of your vault.

USES

• Shielding rooms•High and low energy linear accelerators•Proton therapy•Radiosurgery•CT Image-Guided IMRT•IMRT / IGRT•Other medical and industrial modalities

SWING DOOR SYSTEM SUPPLIER: RPP, USA

RPP’s swing radiation shielding doors (neutron doors) are constructed with ¼" thick A-36 steel face plates. A-36 steel flat bars are used for the stiles and the reinforcement inside the door . Flat bar thicknesses for the stiles and reinforcement are dictated by the core of the door. The core of the door will consist of the shielding requirements (typically lead and borated polyethylene) as determined by a licensed physicist. We can also design the door with extra space inside for future upgrades which may require more shielding. The door finish is completed in the factory with a paint grade primer. RPP offers safety features for radiation shielding doors (neutron doors) such as motion sensors, pressure sensitive tape, and battery backup.

Our RPP designed frames for neutron swing door systems are constructed with ¼" thick A-36 steel. Five gussets at ¼" thick and five pieces of bent flat bar steel at ½" thick are welded to the jambs (see detail-link). This reinforcement ensures longevity for the radiation shielding door (neutron door) and prevents misalignment between each of the hinges. The gussets have a dowel system to allow the concrete to set securely to the frame when poured. This RPP designed framing system is the most durable available.

RPP’s automatic openers for radiation shielding doors (neutron doors) are the most reliable and well-built in the industry. Our vendor’s vast experience of what works and what does not is based upon years of field experience. The 1502 series electric operators are specifically designed to eliminate the problems that other manufacturers have had with their designs. The units are built with the very best industrial components on the market today. Specific issues like output shaft failure, limit switch sensitivity, torque output, torque output control, operator mechanical drive protection, and door inertia control are all diminished or eliminated by design. The electric operators require a 120 VAC power source that we convert to 90 VDC. The advantage of DC is that we can better control the operation of the door operator. RPP will make final adjustments to the door but all conduit work and electrical work will be completed by others. See more details on swing door operators.

SWINGING DOOR OPERATOR

RPP’s radiation shielding doors (neutron doors) and door frames are customizable to meet both your new construction requirements and you retro fit requirements.

For frames set in concrete, the frames will be shipped to the jobsite with detailed specifications to be installed by an independent contractor. Retro-fit frames will be installed by RPP

MRI SHIELDING SYSTEMS

DKS builds high quality, dependable, state-of-the-art MRI facilities. We offer two types of RF shielding to accommodate varying customer needs, MRI system specifications, construction requirements, and facility locations:

•Galvanized modular panel system•Soldered copper sheet system•Guardian Door

Because an MRI shield involves much more than just wall panels, DKS offers several site options and accessories to complete the shield. Learn more about our Optional RF Shield Components, including Magnetic Shielding Options.

We work closely with medical organizations and equipment manufacturers to adhere to all safety and health regulations. After installation is complete, our experts conduct tests to prove that all enclosures comply with the MRI equipment manufacturers’ requirements and industry standards.

USES

• Radio Frequency (RF) shielding for Magnetic Resonance Imaging (MRI) machines•RF shielding for data/voice security, labs, and test rooms•Magnetic shielding for Magnetic Resonance Imaging (MRI) machines

Features and Benefits

• Versatility - can easily be used in new or remodeled rooms• Durability - built for high traffic and high RF attenuation• Customization - dimensions and thicknesses to meet any design need• Testing - complete attenuation and ground testing

RADIATION THERAPY SHIELDING UPGRADES

Since the healthcare industry is constantly changing, shielding upgrades are a common dilemma.

DKS constantly stays up to date with the latest technologies in both radiation therapy and diagnostic imaging, so we are prepared for any shielding upgrade needs. Our team of experts works closely with clients to find the most cost efficient solutions with the available space.

DKS can provide radiation therapy shielding upgrades by supplying and installing all materials, providing a full turnkey installation, or aiding in the design process. The upgrade design scope can include architectural, physics, and structural engineering.

RADIATION THERAPY SHIELDING UPGRADES

Components:

High Density Concrete Block is a space-saving shielding solution for maze and vault walls, as well as ceilings in both new facilities and vault upgrades or renovations. Available in a range of densities, these blocks are suitable for both high and low energy linear accelerator vaults and shield both gamma and neutron radiation.

For maximum shielding integrity, each block is manufactured with our proven shielded tongue and groove interlocking design. To allow for modularity (and providing a potential tax-saving benefit), HD Concrete Blocks can be put in place without mortar. For optimal space and cost savings, this product can be used in conjunction with other materials, such as N-Series Interlocking Lead Bricks, MegaShield, or lead sheet.

USES•Low and high energy linear accelerators•H.D.R. rooms•Proton Therapy rooms•Radio Surgery rooms•CT Image-Guided IMRT Rooms•Industrial and homeland security applications

Interlocking Lead Brick is a space-saving and environmentally friendly solution for adding shielding to an existing vault, or saving space in a new vault design. For maximum shielding integrity, these bricks feature a tongue and grove design that locks into place when bricks are stacked. They can be used in any part of the room, and are most frequently held in place with steel supports.

The lead uses in our N-Series Interlocking Lead Bricks is recycled from both pre-consumer and post-consumer waste, making it eligible for up to two LEED™ credits.

USES

Low and high energy linear accelerators

H.D.R. rooms

Proton Therapy rooms

Radio Surgery rooms

Custom radiation shielding

Nuclear medicine

P.E.T.

Other radiation shielding applications where space savings is a priority, including industrial or homeland security applications

LINEAR ACCELERATOR VAULT SYSTEMS

DKS supplier in USA, NELCO offers a variety of solutions for LINAC vaults in new construction, renovations, upgrades, or additions. We offer a variety of products to choose from, and if required, our value engineering services can help you find the best solution for your needs. Many of our solutions are modular, making them the perfect solution for leased spaces, and allowing the freedom to relocate if needed.

LINAC vaults include those for standard Linear Accelerators, IORT, IMRT, Cyberknife, Gamma Knife, or CT Image-Guided IMRT Rooms.

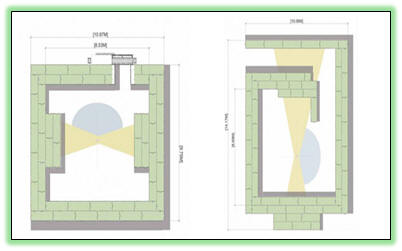

Typically LINAC vaults are designed in one of two configurations, mazed or mazeless.

Mazed Vault Systems

Mazed vaults are the frequently used and allow for a less heavily shielded door system. In facilities where space is not an issue mazed vaults can be a cost effective solution. NELCO’s swing door systems used with mazed vaults can come with a partial open feature, allowing for faster patient throughput.

Mazeless Vault Systems

Mazeless vaults allow for a smaller overall footprint in the facility. It is recommended to use a slide door system in these applications, because the door thickness needs to be increased. However, mazeless vaults typically save approximately four hundred square feet - with the premium construction costs for vaults, this can provide a cost savings of approximately one-hundred thousand dollars per vault.

Mazeless vaults also increase productivity, frequently allowing centers to treat more patients throughout the day, increasing income.

PET/CT SHIELDING SYSTEMS

Unlike most diagnostic equipment, PET/CT systems require thicker shielding. DKS can design and provide PET/CT shielding systems for any machine or room type. Shielding thickness is dependent on a physics design report, which will dictate the type of shielding required. For thicknesses up to 2MM, lead-lined plywood can be used, while for greater thicknesses, Interlocking Lead Brick is recommended.

DKS’s involvement in PET/CT shielding systems can range from design services to supervising construction and installation to providing complete turnkey services. Our qualified teams of designers, engineers and project managers have a proven track record of PET/CT installations throughout the world, and always work one-on-one with clients to create the most cost-effective solutions.

USES

PET/CT Shielding Systems are used for rooms with low energy x-rays and gamma rays.

MEGASHIELD MODULAR BLOCK

MegaShield™ was created by NELCO as a competitively priced, modular alternative to a poured cast-in-place (CIP) vault. Each MegaShield™ system is made up of interlocking concrete blocks, available in both standard and high density weights. These blocks are cast at a local, off-site, pre-approved and qualified facility, allowing NELCO to manufacture them during the permitting process. Blocks arrive on site cured and ready to assemble, reducing construction time significantly. MegaShield™ vaults can be assembled in as little as four weeks.

The system can be erected outside a building, or inside of most existing facilities, and can be used for a variety of modalities. MegaShield™ can also be removed and relocated, making it the ideal solution for leased spaces. When space constraints are an issue, a hybrid model of MegaShield™ and other shielding, such as Interlocking Lead Brick or High Density Concrete Blocks, can be designed. Other options include site work, foundation work, interior finish, and mechanical and electrical systems.

USES

•Linear accelerator vaults•Proton therapy rooms•Shielding CT Image-Guided IMRT•Industrial uses (such as non-destructive testing and homeland security applications

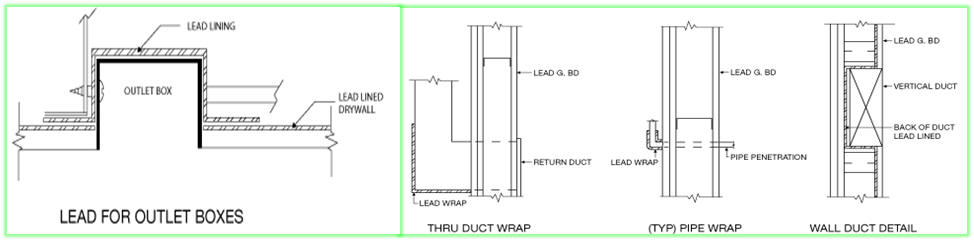

CUTOUTS & PENETRATIONS

When installing lead lined drywall (lead lined sheetrock, lead lined gypsum), all cut outs, seams and penetrations will require sheet lead or lead plate to ensure continuous shielding throughout the room. Proper installation of additional lead wherever penetrations are created will eliminate potential leaks and ensure total protection.

Additional sheet lead can be supplied to easily allow for the proper shielding of penetrations such as receptacles, light switches, ducts and telephone/data cables.

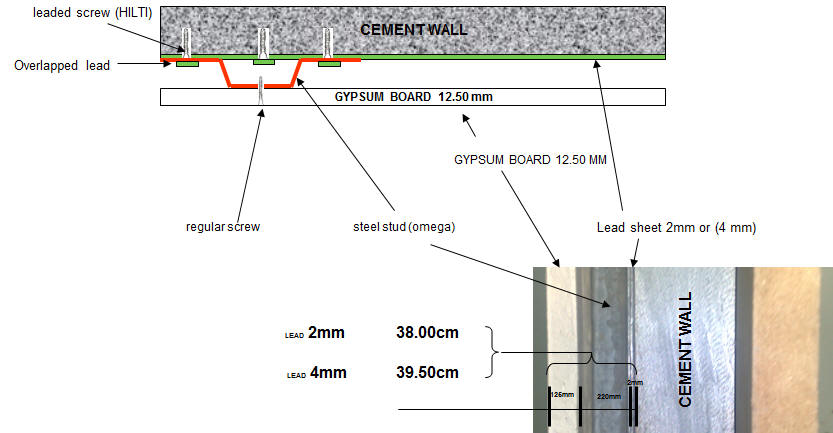

INSTALLATION METHOD

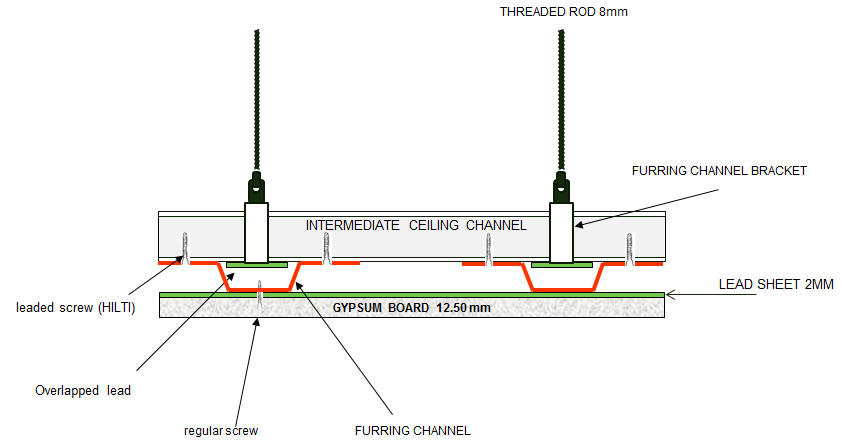

CEILING LEAD LINING METHOD

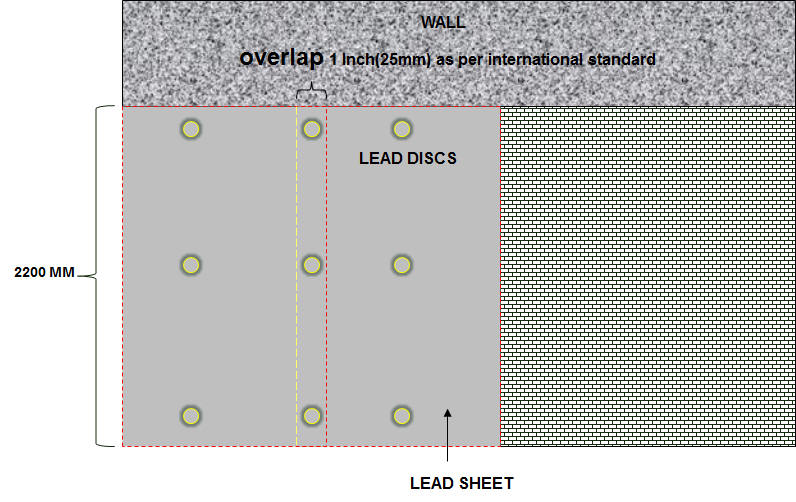

OVERLAPING, LEAD DISCS INSTALLATION

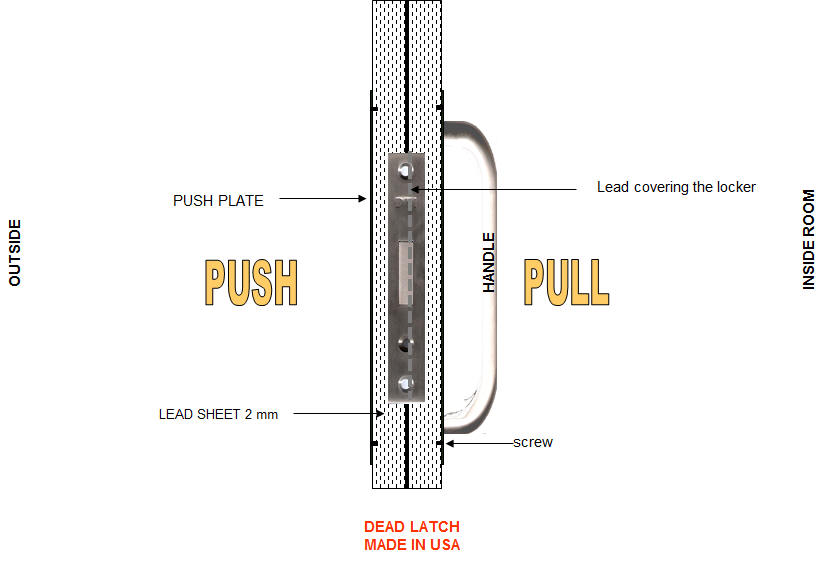

LEAD DOOR HARDWARE

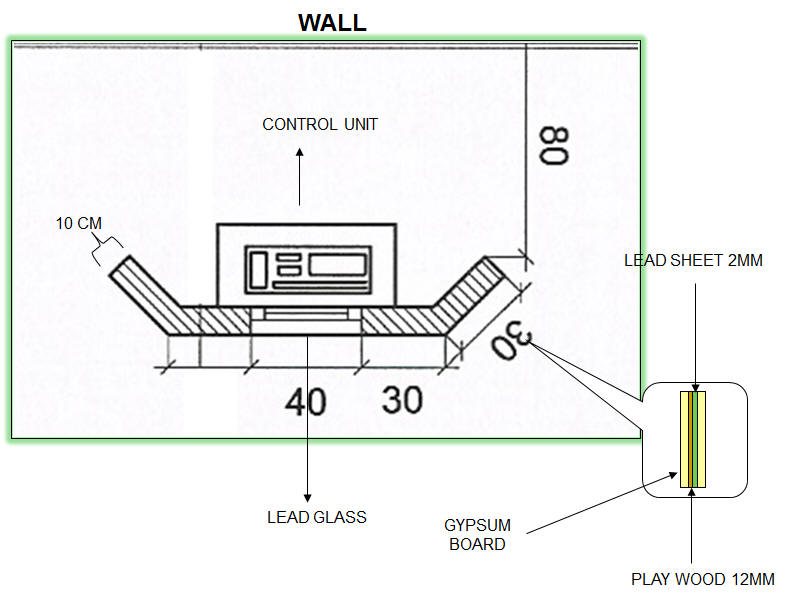

LEAD BARRIER

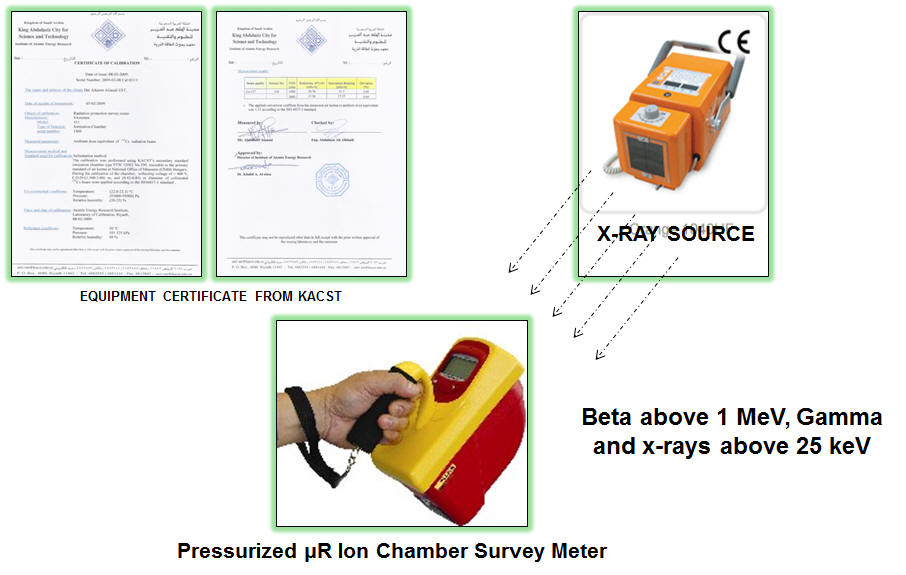

X-RAY LEAKAGE INSPECTION TOOLS

LEAD PRODUCTION LINE

Download Our Profile

![]()

To contact , please send an email to :

Or call :

00966560000780 - 00966505333918